Fixed Electric Chain Hoists are the least risk-bearing hoist models, depending on the durableness of the area at a fixed point. Fixed Electric Chain Hoist, electric fixed wire rope hoist, and tower cranes are mostly used in industrial environments. Periodic maintenance after the installation of Fixed Electric Chain Hoists is a very important issue in terms of safety. You can purchase them from the Dejun with reasonable prices and you can benefit from installation and maintenance services.

The fixed chain electric hoist is a light and small lifting equipment, which is composed of a motor, a transmission mechanism, and a sprocket. The lifting weight is 0.3-32 tons, and the lifting height is 3~120 meters. Chain electric hoist fixed type, also known as hook type, can be used for fixed suspension (fixed chain hoist) and can be equipped with electric monorail car and hand-pushed/hand-pulled monorail car walking use (running electric chain hoist). Beautiful is out looking, Solid Durable. Inside gears are hot-quenched then increases the wear resistance of the gear and toughness. Adopt international advanced technology, fine workmanship, gear wheel tight fit.

Fixed type electric chain hoists are widely used in workshops, warehouses, wind power generation, logistics, docks, construction, and other occasions. This electric hoist can also be used with a gantry frame or bridge crane, can be used for lifting or loading and unloading goods, and can also be used for precision mold installation, debugging, and maintenance. As a hoist and crane manufacturer and supplier, Dejun provides customers with carefree services. Dejun can provide various kinds of fixed electric chain hoists for various applications.

| Capacity(T) | 1-32 | |||||||||

| Lifting Speed(M/Min) | 7.2/2.4 | 6.9/2.3 | 9.0/3.0 | 6.9/2.3 | 3.3/1.1 | 5.4/1.8 | 5.4/1.8 | 4.5/1.5 | 2.4/0.8 | 2.7/0.9 |

| Motor Power(Kw) | 0.8/0.27 | 1.8/0.6 | 3.0/1.0 | 3.0/1.0 | 1.8/0.6 | 3.0/1.0 | 3.0/1.0 | 3.0/1.0 | 1.8/0.6 | 3.0/1.0 |

| Insulation Grade | F | |||||||||

| Power Supply | 3P 220V-690V | |||||||||

| Control Voltage | 24V/36V/48V | |||||||||

| Spec. Of Load Chain | φ6.3 | φ7.1 | φ10.0 | φ10.0 | φ7.1 | φ11.2 | φ11.2 | φ10.0 | φ7.1 | φ11.2 |

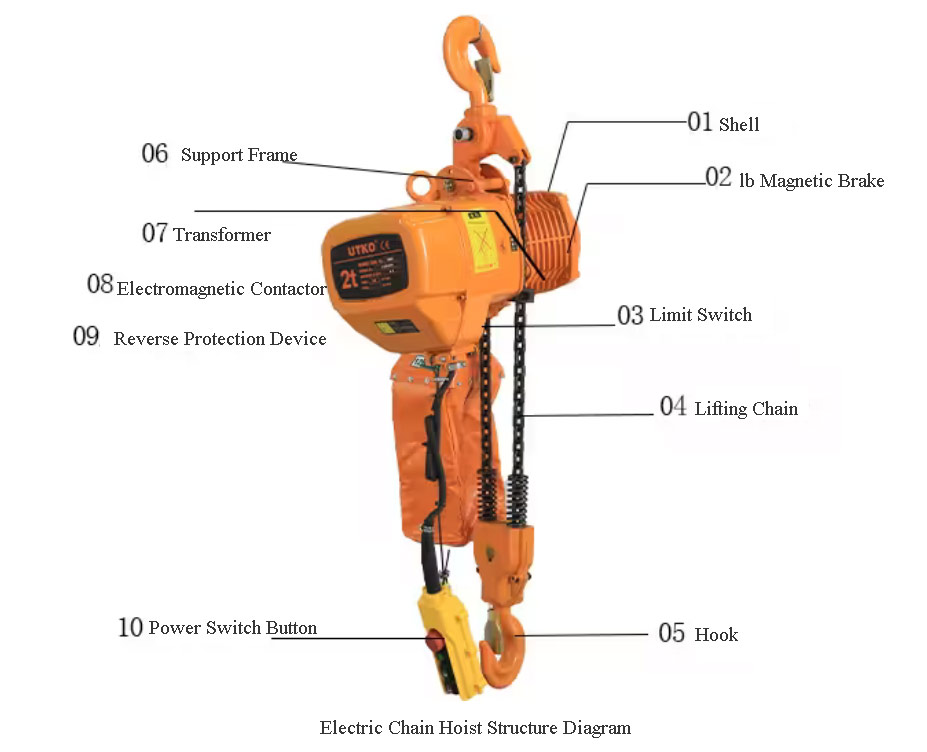

① Outer shell: Aluminum alloy shell, solid and lightweight. Characteristic heat sink, fast heat dissipation, continuous use, efficiency up to 40%. Integral closed structures can be used in chemical plants, electroplating plants, and other places.

② Pound magnetic brake: The purpose is to brake while the power is cut off to ensure the safety of the lifting process.

③ limit switch: The main function is to prevent the hoist chain from exceeding, which can automatically stop in advance and cannot be used as a brake.

④ Lifting chain: The chain adopts an imported alloy steel chain after heat treatment so that it can be used safely in seawater, chemicals, and other corrosive environment without being affected.

⑤ Lifting hook: Hot forging process, the lower hook can be rotated 360, with a safety tongue to ensure safe operation.

⑥ Support frame: The two steel plates bear the lifting force of the electric hoist motor and the hook.

⑦ Potential transformer: 24V/36V transformer. During operation, in case of leakage, accidents can be prevented, and safe use can be ensured when it rains.

⑧ Electromagnetic contactor: It is helpful for the problem of excessive temperature caused by the use of an electric chain block for a long time.

⑨ Reverse phase protection device: Special electrical wiring. It mainly protects the problem of wrong connection of wire and line, and the control circuit cannot operate to prevent burning out the motor.

⑩ Waterproof push button switch: Waterproof switch Waterproof with emergency stop button.

Applied environment

The use of fixed electric chain hoists is very wide, mainly used in major factory buildings, warehouses, wind power generation, equipment manufacturing, logistics, docks, construction, dock and other industries. It can be used for lifting loading and unloading of goods, as well as for installation or debugging of high-precision molds.

Fixed type electric chain hoists are one type of electric chain hoist and fixed electric chain hoists are usually used in fixed lifting places, such as freight elevators. Its advantage is that it is relatively stable, but its disadvantage is that it cannot run. Beautiful is out looking, Solid Durable. Inside gears are hot-quenched then increases the wear resistance of the gear and toughness. Adopt international advanced technology, fine workmanship, gear wheel tight fit.

The fixed type electric chain hoist has a high working level, good safety performance, high reliability and low failure rate. The chain runs in the sprocket, it is not easy to fall or jump, and the use is more stable.

Fixed Electric Chain Hoist Features

Advantages of chain hoist compared with wire rope hoist

① At the same time, the volume of the chain electric hoist is smaller than that of the wire rope electric hoist, because the two structures are not the same.

Chain electric hoist as the name suggests is driven by the chain, and the separation of the chain bag and the hoist host is a big advantage, overcoming the problem of the large volume of the wire rope electric hoist drum, so in volume, the chain hoist is smaller than the wire rope hoist.

The higher the lifting height is, the larger the volume of the wire rope electric hoist is than that of the chain hoist because the wire rope of the wire rope hoist is wound on the reel, so it has a greater impact on the volume.

② At the same height of the track, the lifting height of the chain electric hoist is higher.

For the wire rope electric hoist, the wire rope is wound on the drum, the inside of the wire rope is compressed, and the outside is strained. Therefore, the diameter of the drum cannot be too small, only the diameter of the drum is greater than 20 times the diameter of the wire rope, in order to ensure that the stress on the wire rope will not exceed the allowable stress.

There is no mandatory requirement for the sprocket diameter of the chain hoist, and it can be made much smaller than the steel wire rope drum of the same tonnage.

③ under the same track length, the operating distance of the chain hoist is longer than that of the wire rope.

The drum of the wire rope electric hoist is generally arranged along the running track of the hoist and occupies a large space. The sprocket of the chain hoist can be arranged vertically with the track, and the size of the sprocket itself is smaller than the drum size so that the effective distance that can be achieved when the chain hoist is running is significantly greater than the wire rope hoist.

④ The positioning of the chain hoist is more accurate than that of the wire rope hoist.

When the chain hoist is raised, the chain passes through the sprocket to achieve the effect of straight up and straight down.

The steel wire rope hoist below 5t is mostly a single rope type, when the hook is up and down, the hook is also moving around along the direction of the reel due to the steel wire rope moving around on the reel, and the relative positioning is not accurate enough.

Advantages Of Fixed Electric Chain Hoist

Certificate: ISO9001: 2008, CE.

Rotation stability, high efficiency, and labor-saving.

Small size, lightweight, nice appearance.Compact structure.

Custom electric chain hoist as you want for your application.

All around electric chain hoist services from hoist design, manufacturer, delivery, installation, to maintenance.

Precautions when using

① Before use, it is necessary to carefully check the mechanical parts (such as hooks, lifting chains, brakes, etc.) and lubrication, and consider them intact before use.

② Before lifting, check whether the upper and lower hooks are fastened, and the hooks should not be skewed or heavy objects hanging on the tip of the hooks. The lifting chain should be suspended vertically, and there should be no wrong twisted chain links, so as to avoid the chain getting stuck when lifting, affecting the normal work of the machine parts.

③ Before lifting heavy objects, it should be estimated whether the weight exceeds the rated load of the chain electric hoist, and not overload it.

④ When using the chain electric hoist, the hanging object should be tied firmly, there are no obstacles around, and the command information can be clearly received.

⑤ When lifting heavy objects, personnel are strictly prohibited from doing any work or walking under heavy objects to avoid personal accidents.

⑥ In the lifting process, whether the weight rises or falls, the speed should be uniform and slow, do not suddenly accelerate and decelerate, so as to avoid the crash of the goods.

⑦ If the user finds that the pull cannot be moved, he should immediately stop using. Check: whether heavy objects are involved with other objects; Hoist parts are damaged or not; whether the weight exceeds the rated load of the hoist.

FAQ

Q: How many types of chain hoists are there? Which one should I choose?

There are three main types of electric chain hoists: fixed chain hoists, running chain hoists, and low-headroom chain hoists.

Fixed chain electric hoist can only run up and down, and cannot walk around.

Running chain electric hoist can run up and down, but also can walk around, the use of space is larger and more convenient.

Low clearance chain hoist is a kind of running chain hoist, which can walk on the I-beam. Different from the running type, the low headroom chain electric hoist can save space, which shortens the limited distance between the upper and lower hooks, and is generally used in plants with limited lifting height.

The environment used by each electric chain hoist is different, and the specific use of which chain hoist needs to be combined with the specific situation, please consult us for a clearer answer.

Q: How to choose the right electric chain hoist?

In order to choose the "perfect" electric chain hoist, you need to consider the following factors: lifting weight, lifting height, lifting speed, frequency of use, power supply voltage, and the environment used, in addition, if you have other special requirements for it, please let us know.

Q: Why choose us?

① Customizable product

Due to the different working conditions (temperature, humidity, product height, lifting weight, lifting height, etc.), we will design and customize different lifting solutions for you according to your other special needs.

② fast delivery

After receiving your advance payment, we will arrange the production as soon as possible, and the general production delivery time is 7 days.

If you have higher requirements on the production and delivery time of the goods, please be sure to tell us before signing the contract.

③ Lowest price guaranteed

We promise to always provide high-quality electric chain hoists at the best price, we strive to offer the best price on our website and never sell poor quality defective products.

④ All products are fully approved

The company's current qualification certificates are CE certificate, SGS certificate, ISO certificate, etc.

All our factory equipment must be inspected and correct before delivery;

If you have questions about us, please consult us for more detailed qualification certificates.

⑤ Flexible payment methods

We accept T/T bank transfers, L/C, and PayPal.

For regular customers, we can provide more supportive payment terms, such as credit cards.

⑥ 5 Star Customer Service

For large amounts of orders, the team will assist in follow-up and service and set up a project team according to the progress of the project. The members are: project manager, project leader, design engineer, product production & packaging & domestic transportation responsible person, quality inspection personnel, customs clearance & customs clearance responsible person, and one-stop service, each link has a special person responsible for accurate docking and timely service.

⑦ High quality and efficient after-sales:

Provide equipment installation instructions, drawings, and other materials + online/offline assistance in installation, and commissioning, until the equipment works normally;

7*24 hours online service, understanding customer problems within 24 hours to provide solutions;

During the warranty period, due to the damage of equipment parts caused by quality problems, the company will send spare parts free of charge through international express;

The team visits all the cities or countries of the customer, such as exhibitions, installation, etc., free of charge to the customer's factory for equipment testing and maintenance.

Q: What is the minimum order quantity for this product?

1 set.

Looking forward to hearing from you

Contact us for any information you need or for a quote, you can contact our sales team directly or complete the form below, we will reply you promptly.

Related Product